What is XCD?

The pursuit of perfect wood stabilisation has long been hindered by a fundamental, invisible barrier within the wood itself.

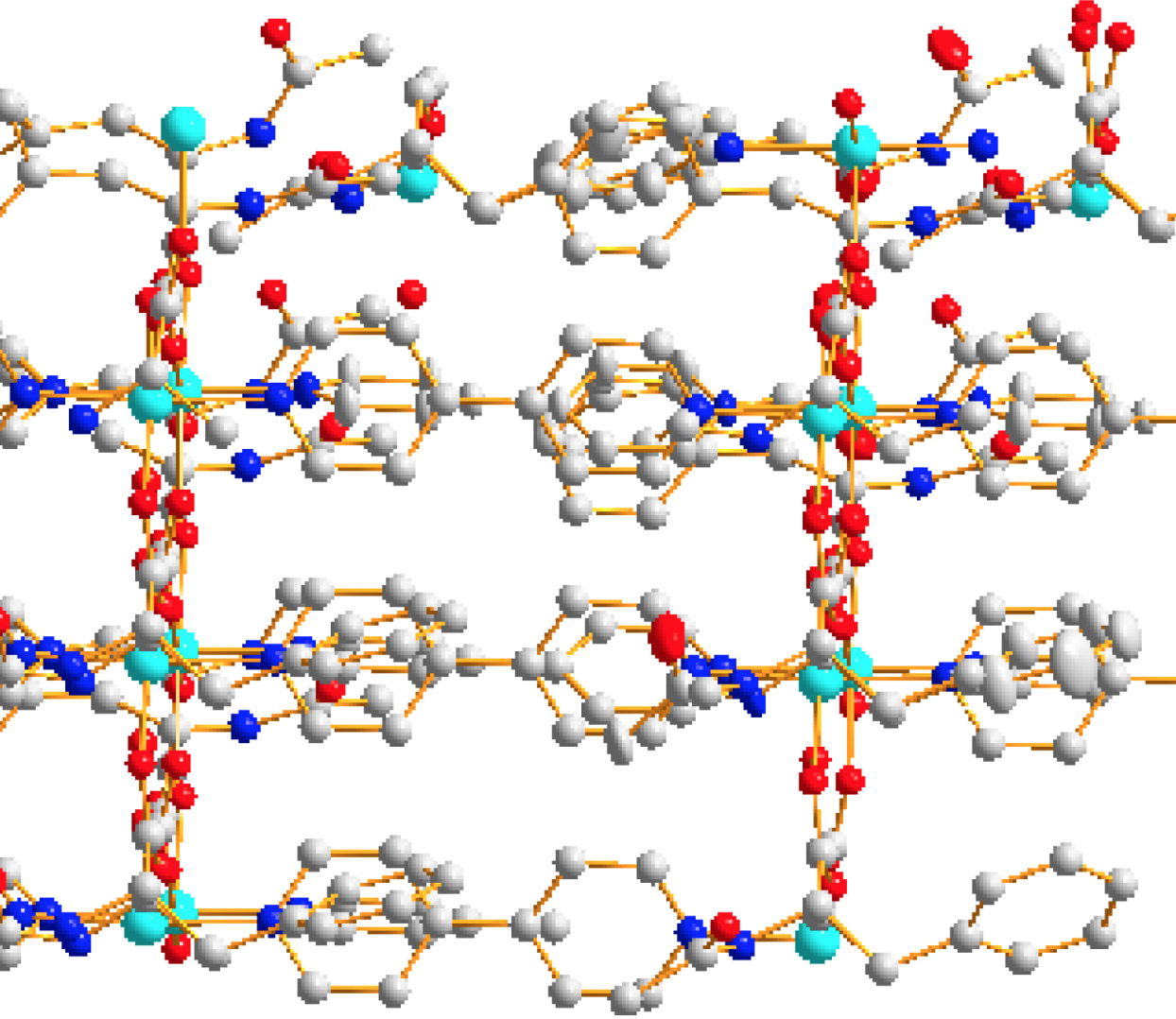

Xylemic Cavitational Delipidation (XCD) is the proprietary pre-treatment process engineered to systematically dismantle this barrier. It is not a mere cleaning step, but a targeted surface preparation protocol that operates at the molecular level to transform the wood-resin interface from a point of failure into the strongest part of the composite.

Overcoming the Weak Boundary Layer in Stabilisation

In advanced wood composites, catastrophic failure is rarely a story of polymer fracture. More often, it is a clean, disappointing delamination where the synthetic resin pulls away from the natural wood substrate on a molecular level.

This points not to a weakness in the impregnating resin itself, but to a fundamental flaw in preparation, the presence of a weak boundary layer at the wood-resin interface. Achieving true, dimensional stability requires moving beyond just impregnation to address adhesion at the molecular level.

Why Wood's Own Biology Limits Conventional Stabilisation

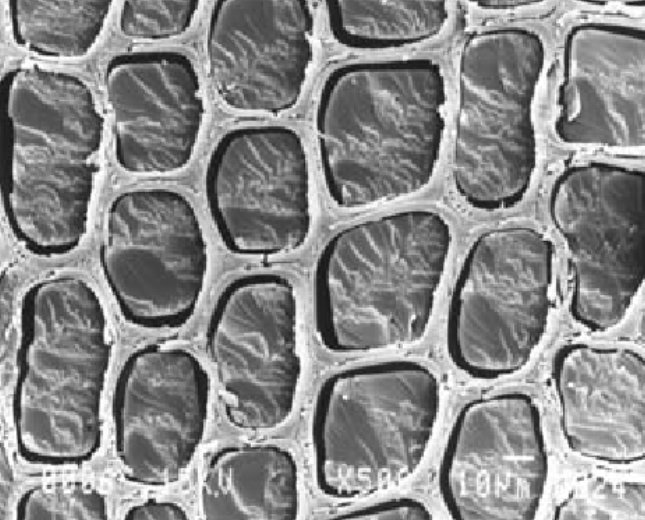

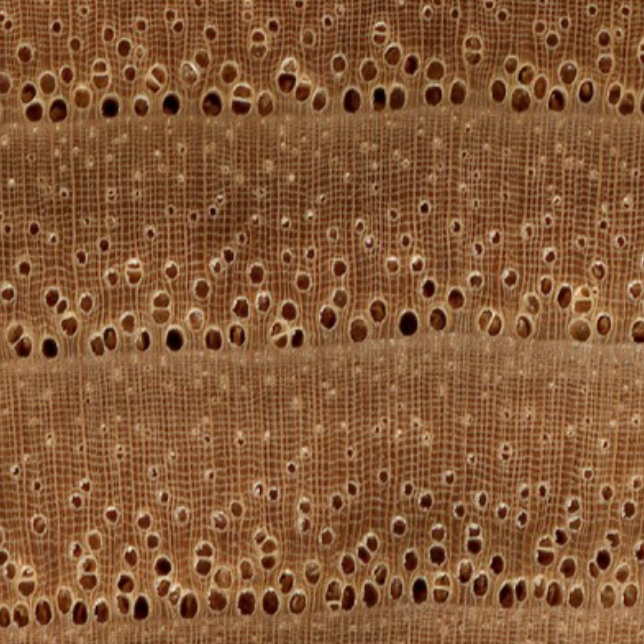

To understand why even expertly executed resin infusion has a performance ceiling, we must look beyond filling voids and examine wood's inherent, complex architecture.

Wood is not a passive bundle of straws, it is a sophisticated biological composite. Its notorious dimensional instability originates not in its empty spaces, but in the chemistry of its solid cell walls.

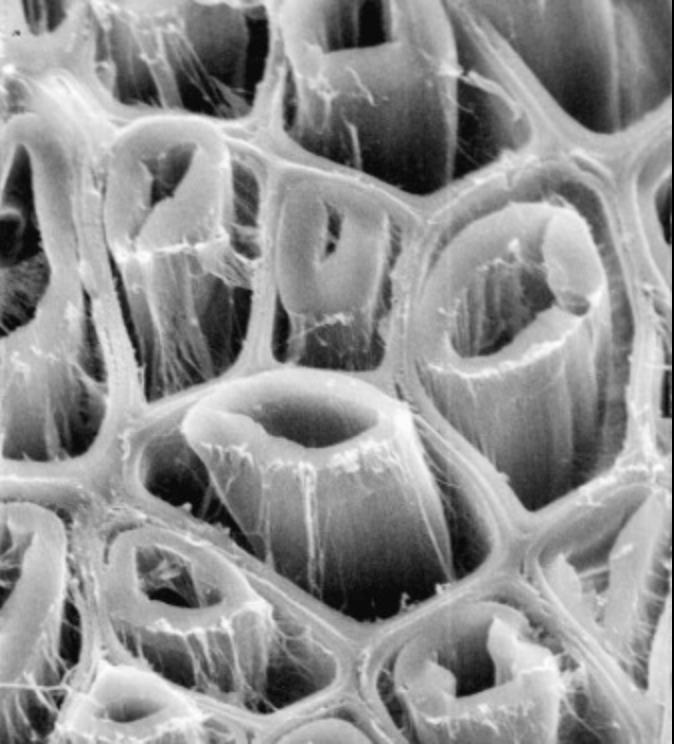

Overcoming Surface Tension for Complete Penetration

In the pursuit of perfect stabilisation, the vacuum chamber is usually seen as the ultimate tool. Yet, there is a fundamental, often overlooked physical force that limits its efficacy, surface tension.

This creates a hard boundary for vacuum-based impregnation, leaving the most critical parts of the wood's structure vulnerable.

How Polymer Science Dictates the Machinability of Stabilised Wood

For the maker, the ultimate test of a stabilised blank happens at the bench. Whether it turns cleanly, sands to a fine dust, or polishes to deep clarity, is the direct result of the polymer network within.

This is not accidental, it is engineered at the molecular level through the deliberate management of two competing principles, crosslink density and chain mobility

Understanding the Physics of a Hard Vacuum

In stabilisation, we operate in the realm of a rough vacuum, typically between 1 and 10⁻³ Torr (mm Hg).

At this level, the environment inside your chamber and wood undergoes a fundamental physical shift.

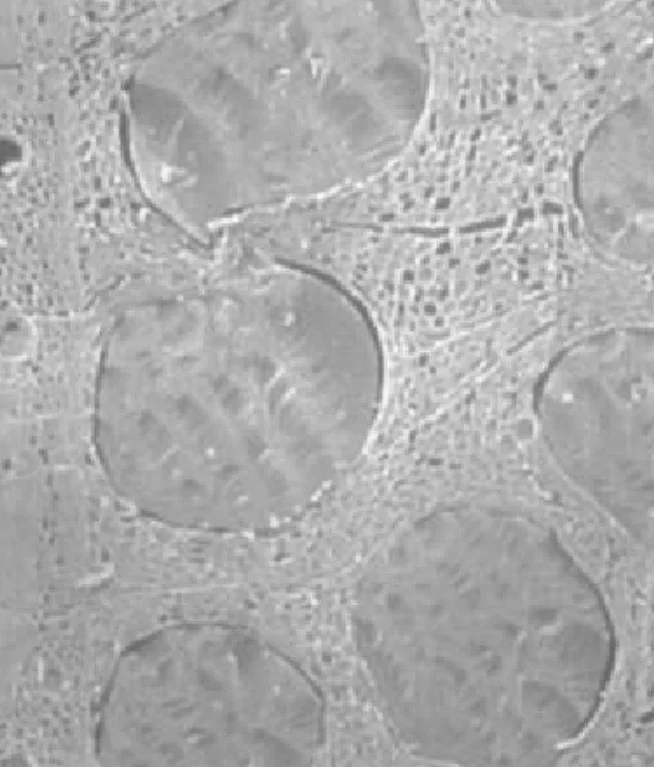

Why Can Moisture be so Destructive in Stabilised Wood

Moisture in wood isn’t just “dampness”, it’s an active chemical threat.

I don’t just see drying as prep, It’s the first reaction in a complex stabilisation process, and it’s where most failures begin.

Vacuum vs Pressure in the Stabilising Process

Vacuum and pressure aren’t just steps in the process, they’re two completely different forces working at a cellular level to transform wood into something knife-worthy.

If you treat them like a checklist, you’re not stabilising. You’re basically just surface-coating.

How Density Affects Stabilising

Density isn’t just “heavy” or “light”, it’s a microscopic blueprint that dictates how resin moves, flows, and locks into place inside a block. Every wood species is its own engineered challenge, with unique internal architecture that either welcomes resin in… or shuts the door in its face.

What is Stabilised Wood?

I am regularly asked what is stabilised wood?

How do I know if a piece of wood is stabilised?

Does this wood need to be stabilised?

How do you stabilise wood?

How much does it help?

Warping

Why does Stabilised wood sometimes warp?

Can it be fixed?

How can I mitigate these issues in future?

I tried to stabilise my own wood and it warped! What happened?

How to Finish Stabilised Knife Handles

Knife handles can be difficult to finish. They will be handled, so soft finishes are not really suitable, and even the highest mirror sheens will dull with use. These handles are also usually made with extremely dense, oily, figured or stabilised woods. These require different finishing techniques to other applications